The topic for our sixth meeting of the Arts and Humanities Research Council funded Glove Network, was the embroidery and embellishment of historic gloves, and Glove design in more recent times.

Rebecca Unsworth, Research Assistant at Birmingham Museums Trust, whose area of specialism is researching into the production and fashionability of gloves in the 16th and 17th Centuries, their exchange and movement across Britain and Europe, and their relationship to news.

Today, we learnt all about glove embroidery and embellishment from that period. We heard that all surviving gloves from that period of time (mostly in museum collections) are heavily embellished with a mixture of silk threads, metal threads, seed pearls and lace. It seems that not all gloves from that period were quite so intricately embellished and, in fact, paintings from the time depict gloves that were not so decorative as those that remain today. Nobility and royalty are often shown wearing plain leather gloves so, perhaps over time, those that are the most visually appealing have been deemed more worthy of being kept by collectors. Plain gloves less so and therefore to be found less in collections today.

Rebecca shared with the group some details of her extensive research telling us that, clothing was frequently heavily embroidered and the gloves worn with the clothing were relatively plain, yet still regarded as highly fashionable. Many people at that time owned huge numbers of gloves, with around 170 pairs being quite normal. Inventories of leather that Rebecca has researched have shown that a variety of animal skins were used for making gloves, including sheep, fox, lamb, dog and possibly cat. However, not all leathers were considered equal and this was reflected in the price of the gloves. Only very supple leathers could be rolled up and held in the hand, as is so often depicted in portraiture. Perfumes were applied by the glovers themselves when making the gloves or sometimes by a perfumier. These included oils from jasmine, cedar, almond, and white lily amongst others. We learn that the question of whether gloves were perfumed before or after embroidery application is still in dispute.

Rebecca shared with us the details of the two ways in which embroidery could be applied to gloves; one was to be worked on a separate gauntlet which was afterwards attached to the glove, the other was to embroidery directly onto the gloves. Longer gloves provided more space for decoration but in both cases, we learnt that embellishment and embroidery was likely to have occurred when the glove pieces were flat prior to sewing together. This required the gloves to be moved between different workshops for each process.

Apparently, pasteboard was often fitted between the gauntlet and the leather to provide support for the embroidery, and this could cause the glove to be heavy to wear.

Rebecca emphasised that other forms of decoration were also popular at this time, such as pinking, whereby a hammer was used to make small holes in the leather itself, to create patterns, but also providing ventilation. In some cases, pinking allowed other fabrics set beneath to be visible, as part of the design. The application of ribbons was another means of applying decoration to gloves for men and women, since they could complement ribbons on the main item of dress. For example, ribbons on a man’s doublet or the ladies matched their glove ribbons with other small accessories, and Rebecca shared visual examples of these with the group.

It was fascinating to learn more of the approach to the design of gloves during this period, and their relationship to other items of clothing.

Isabella Rosner is an art historian who studies material culture from the 17th through 19th century. An expert in the study of early modern women’s needlework, especially British examples, and samplers across all time periods. Isabella is a PhD student at Kings College London, who has researched embroidery on 16th and 17th century gloves, studying the shared motifs on gloves and contemporaneous domestic and professional needlework, including purses, caskets, wall friezes, and other decorative items.

According to her findings, there was a desire to stitch similar themes things in domestic work but at the same time, some motifs seen on gloves don’t appear in domestic embroidery. Hunting scenes are often depicted on both gloves and domestic items as are sea monsters. Isabella shared examples of these themes rendered in needle lace cutwork and white work embroidery too. The interest in sea monsters reflected the expanding world in which the population did not know what would yet be discovered, reflecting the mysticism of what was yet to be explored. We learnt that the collection of gloves belonging to the Glove Collection Trust contains examples of motifs of sea monsters on gloves dated from 1600-1620. Embroidery provided both the opportunity to use a variety of stitches including French Knots, and the opportunity for textural effects using chenille amongst other threads.

Other popular motifs of the time were flowers, and fruits such as strawberries and grapes, and this pattern was ubiquitous. Grapes, we learn were used on gloves, sweet bags, and samplers with nearly all of the grapes being the same shape and configuration. This stylised motif can possibly allude to religious meaning, referencing Christ turning water into wine, being universal imagery.

We learn that pattern books originating in Germany and Italy were often translated into English and French and may have been part of the print culture which was both spread officially but also by word of mouth. These books were also reference material for needle lace and fashion in general. It was truly fascinating to learn from Isabella that the same aesthetic conclusions that were reached for different ends and to contextualise the embellishment of gloves with other domestically embellished items.

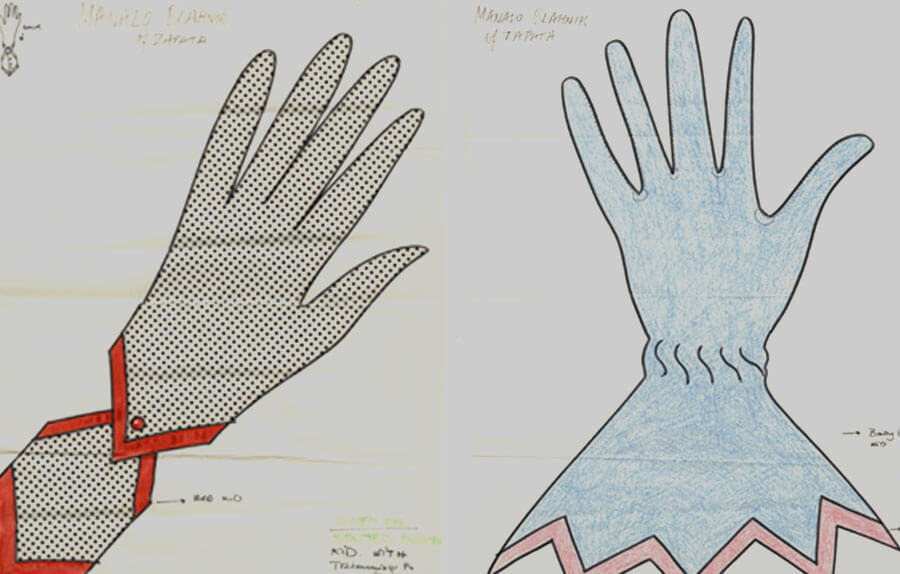

Valerie Wilson Trower was the Design and Development Manager of Southcombe Gloves for many years as part of her career as a glove designer. Southcome still produce high end leather gloves today. This was her first experience of glove design, she told us, during which she quickly realised that there was a great deal more to glove design than simply colour and trims! She realised that three-dimensional design was of the essence. So too the importance of selecting the right materials and using them to create design interest. An important part of her role was to liaise with the product development teams and buyers of the high street companies and high-end designer brands who were going to buy the exclusive glove designs for their own ranges.

There is software today to help with the development of glove design when, historically, designs had to be hand drawn before first prototypes could be made. The importance of treatments and finishes applied to the leather was also a key part of the role when designing and developing glove ranges.

It is interesting that today, many companies making gloves in the UK do not employ a focussed glove designer perhaps because simpler styles are most popular and more economical to produce, although there is still a market at the very high end for designer gloves.

Our session on the embroidery, embellishment and design of gloves was really insightful and we give a huge thanks to our three speakers at this fascinating event.